DOWNLOADS

TÉLÉCHARGER

Faits saillants de L'education

Faits saillants de WOODWORKS

Faits saillants de THINK WOOD

Faits saillants de AWC

APERÇU

REPORTAGE

DU SLB

Propriétaire |

Idaho Forest Group

la vidéo correspondante.

Chef de la direction | Gorman Group

Président et chef

de la direction |

The Westervelt Company

Faits saillants du 3e trimestre

de pieds carrés

à ce jour

en bois massif

ossature de bois légère

890 000

de CO2 évitées

610 000

de CO2 stockées

280 000

Mercer Court | Ankrom Moisan Architects |

Photo : WG Clark Construction

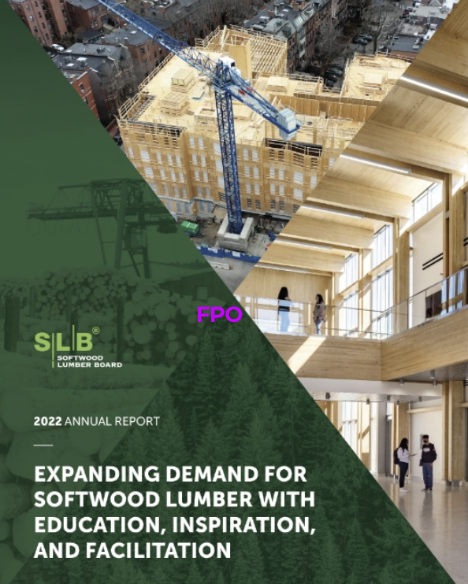

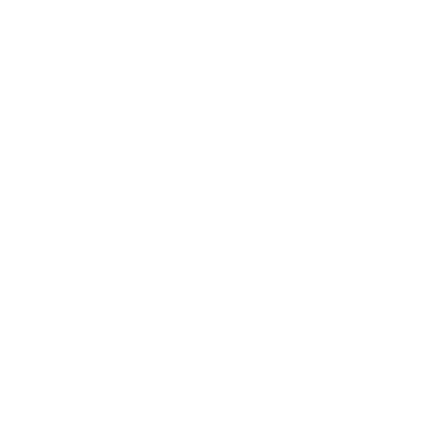

Depuis 2015, les programmes financés par le SLB ont permis de convertir 2 300 projets d’habitation multifamiliale et 1 500 projets non résidentiels au bois d’œuvre. Chaque tranche de 100 $ investie par le SLB engendre un financement externe additionnel de 96 $ provenant de partenaires comme le USDA Forest Service, ce qui multiplie le rendement et prolonge l’effet sur le marché.

Un plan stratégique récemment approuvé profite de cet élan en recentrant l’attention sur les domaines qui génèrent des résultats : la conversion de projets (WoodWorks), l’intérêt pour la spécification (Think Wood), le soutien des codes du bâtiment (AWC) et les projets d’enseignement qui façonnent la nouvelle génération d’architectes, d’ingénieurs et d’entrepreneurs. Le programme d’accélérateurs urbains du SLB (qui va de Boston, de New York et de la Géorgie à Portland, en Oregon, et à Santa Monica, en Californie) a directement soutenu plus de 40 projets novateurs en bois, et d’autres villes devraient s’ajouter à cette liste en 2026.

En investissant dans le SLB, l’industrie renforce sa position actuelle sur le marché et garantit une demande supplémentaire pour l’avenir. En savior plus.

Alors que le segment des habitations unifamiliales est en baisse de 4,9 % à ce jour cette année, les producteurs de bois d’œuvre résineux subissent une pression renouvelée en raison de la volatilité des marchés et de la concurrence de l’acier, du béton et des composites. Le SLB demeure un joueur de premier plan dans la stabilisation de la demande et dans l’expansion de la portée de l’industrie dans les marchés multifamilial et non résidentiel.

« Notre industrie est confrontée à un problème de demande », admet Ashlee Cribb, vice-présidente de la division des produits de bois d’œuvre chez PotlatchDeltic et seconde vice-présidente du SLB. « Les sommes investies dans le SLB sont essentielles à l’expansion et à la croissance des marchés destinés à nos produits ».

Ashlee Cribb

Vice-présidente de la division des produits

de bois d’œuvre chez PotlatchDeltic

Seconde vice-présidente, conseil d’administration du SLB

Coordination du programme du SLB

Stratégie de croissance à cadre léger

Concours de bois massif K-12

Consultez ces articles.

Vous aimeriez lire d’autres reportages du SLB?

BuildFest 2025 | Flux

Photo : Breyden Anderson

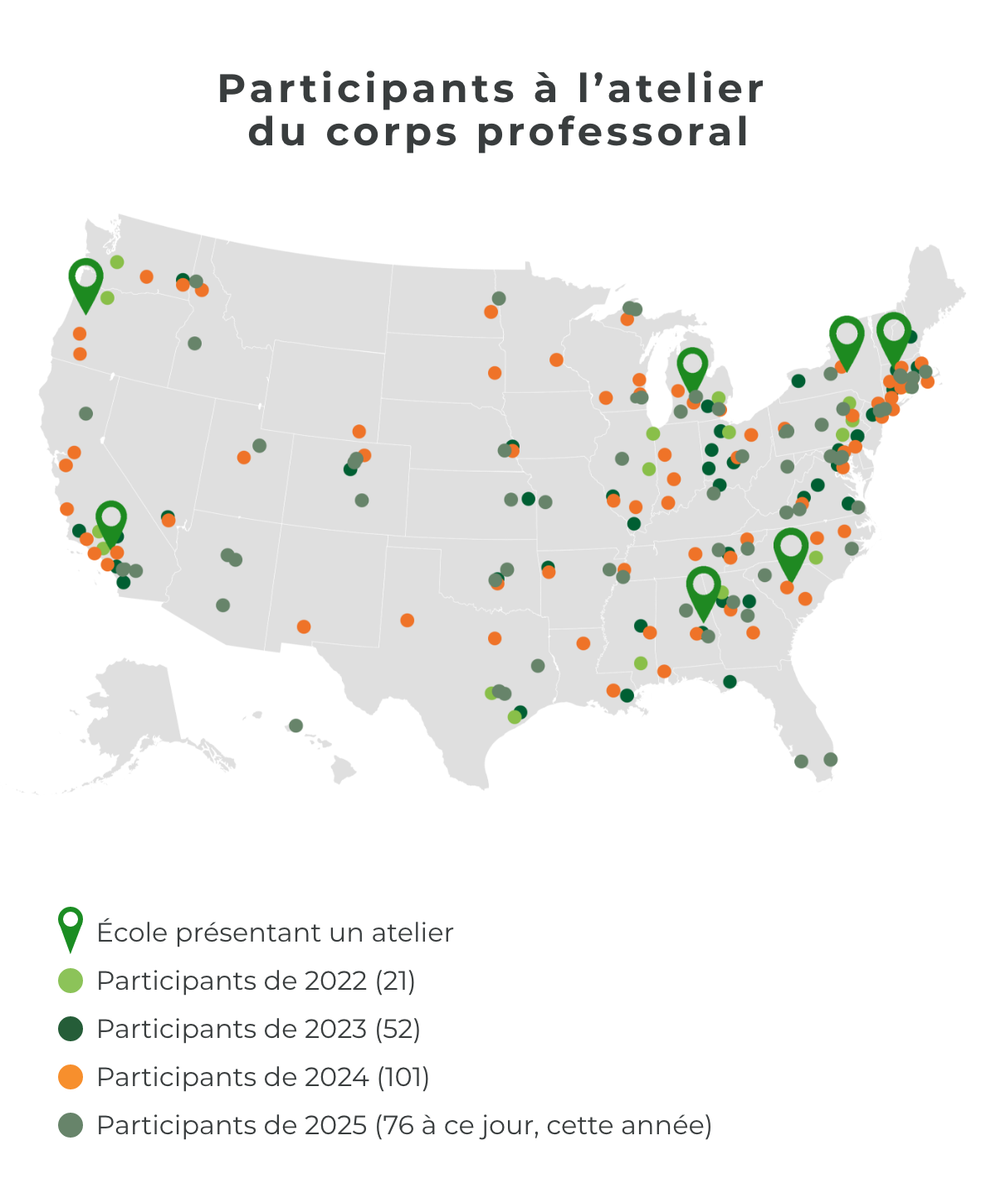

Pour faire croître la demande à long terme de bois d’œuvre résineux, il est primordial de faire progresser l’enseignement supérieur axé sur le bois.

Pendant cinq jours de septembre, les étudiants ont campé et collaboré pour ériger des installations interactives à grande échelle en bois sur le site du festival de musique historique de Woodstock.

La prochaine vague d’architectes et d’ingénieurs déterminera la nature des matériaux qui formeront nos villes; le SLB veille à ce que le bois d’œuvre soit au premier plan de leur esprit dès le premier jour.

connaissances sur les solutions en bois et une préférence pour ce matériau aux professionnels établis et nouveaux ainsi qu’aux éducateurs.

BuildFest 2025 | Peace Pavillion

Photo : Breyden Anderson

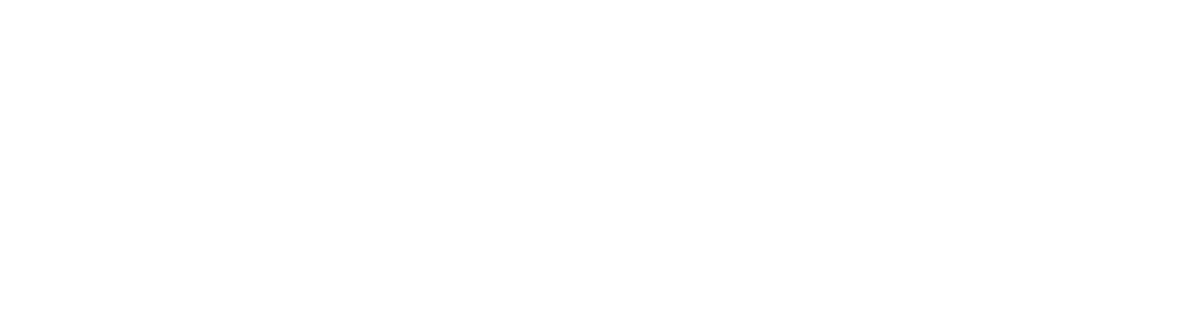

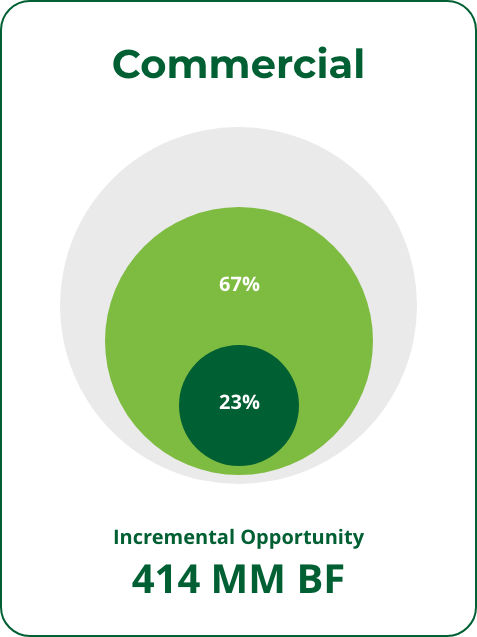

Le nouveau plan stratégique du SLB vise à générer 2,9 milliards de pieds-planche de demande supplémentaire annuelle d’ici 2035, dont près de 1,4 milliard (environ 47 %) devrait provenir de la construction à ossature de bois légère, principalement dans le segment de l’habitation multifamiliale. Le chemin le plus rapide vers le volume est clair : se concentrer sur l’« entre-deux manquant » (les habitations qui font le pont entre les maisons unifamiliales et les édifices de grande hauteur), en plus des projets abordables où l’ossature de bois légère domine déjà sur le plan des coûts, de la rapidité et de la reproductibilité.

Cette stratégie s’appuie sur des gains confirmés et encourage les programmes financés par le SLB (l’AWC, Think Wood, WoodWorks et la division de l’éducation) à convertir d’autres projets d’habitation multifamiliale d’un à huit étages en faisant la promotion croisée des propositions de valeur bien établies de l’ossature de bois légère et des systèmes hybrides à ossature de bois légère et en bois massif. Parmi les mesures prioritaires figurent l’accélération de l’adoption des codes, le développement du soutien technique des projets et le renforcement de notre portée dans les régions qui présentent le plus de possibilités de croissance.

Du côté des promoteurs, l’analyse de rentabilité est éloquente : la diminution des délais de construction permet de réduire les coûts de financement, la rapidité accrue des locations permet d’accélérer le flux de trésorerie et les systèmes hybrides (comme les intérieurs en ossature de bois légère avec planchers ou noyaux en bois massif) offrent rendement et souplesse de conception sans gonfler les budgets.

Ces avantages permettent d’augmenter le revenu net d’exploitation tout en réduisant

le risque de livraison, ce qui joue un rôle primordial dans un marché du crédit

sous tension.

En concentrant les investissements dans les secteurs où les avantages de l’ossature de bois légère sont éprouvés et où l’adoption peut croître rapidement, le SLB dirige le bois d’œuvre vers une croissance annuelle soutenue et reproductible de 1,4 milliard de pieds-planche dans le seul secteur de la construction à ossature de bois légère. Découvrir la stratégie du SLB.

Williams College Davis Center | Leers Weinzapfel Associates |

Photo : Albert Vecerka Photographs

Alors que la demande d’une construction de moyenne hauteur efficace augmente, WoodWorks dote les architectes, les ingénieurs et les entrepreneurs des compétences leur permettant de concevoir des bâtiments à ossature de bois légère de plus en plus imposants.

aide les professionnels à tous les stades

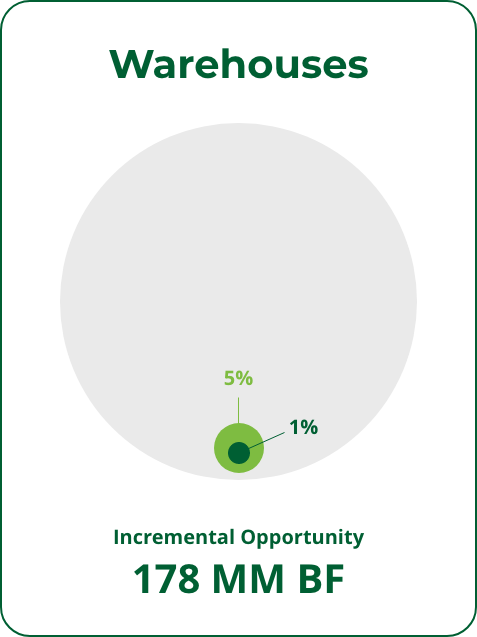

WoodWorks fait du bois une solution viable et évolutive pour les entrepôts, les centres de distribution et les centres de données, des segments qui représentent des débouchés importants pour la demande supplémentaire de bois d’œuvre.

de données et les entrepôts

Alors que de plus en plus de catastrophes naturelles touchent les collectivités et qu’il y a une demande croissante de logements résilients créés rapidement, la construction en bois, en particulier les systèmes à ossature de bois légère et préfabriqués, offre une avenue qui a fait ses preuves

Williams College Davis Center | Leers Weinzapfel Associates |

Photo : Albert Vecerka Photographs

Ce projet de Portland, en Oregon, se compose de deux tours de quatre étages faites de planchers insonorisés en bois lamellé à goujons et de poutres et colonnes en bois lamellé-collé.

École secondaire de Cleveland

Le SLB et le USDA Forest Service ont annoncé les gagnants de la compétition sur le bois massif de 2025 : bâtir des écoles durables, qui attribue 1,8 million de dollars aux projets qui démontrent le pouvoir transformateur du bois massif sur la conception d’écoles de la maternelle à la douzième année. La compétition, qui en est à son troisième cycle, continue de faire croître la part de marché du bois d’œuvre dans le secteur à volume et à visibilité élevés de l’enseignement public.

Les écoles récipiendaires, de l’Oregon à Washington, D.C., démontrent la capacité du bois massif à produire des bienfaits mesurables : meilleure concentration des élèves, bien-être des occupants, réduction des délais de construction et réduction de l’empreinte carbone. Pour les investisseurs, le segment de la maternelle à la douzième année constitue l’une des possibilités de croissance les plus évolutives. Les projets retenus représentent des modèles conformes aux codes qui peuvent être reproduits partout aux États-Unis.

En intégrant la conception biophile et des matériaux durables, ces projets montrent que la construction en bois peut surpasser les systèmes classiques en matière de rentabilité, de durabilité et d’effet sur les collectivités. Chaque projet dévoilera ses données de performance et ses perspectives de conception afin d’accélérer l’adoption du bois dans les commissions scolaires. Par l’intermédiaire de la compétition sur le bois massif, non seulement le SLB finance l’innovation en conception, mais il permet aussi d’accroître la demande de bois d’œuvre résineux dans un segment de marché essentiel qui crée de la valeur pour les collectivités et, à long terme, pour l’industrie.

La compétition sur le bois massif est un autre exemple du partenariat entre le SLB et le USDA Forest Service pour débloquer l’innovation dans l’ensemble du secteur de la construction. Depuis l’officialisation de leur collaboration par l’intermédiaire d’un premier protocole d’entente en 2015, le SLB et le Forest Service ont conjointement investi près de 100 millions de dollars dans des programmes et des compétitions qui visent à élargir les marchés du bois d’œuvre résineux et à lui conférer le statut de solution de construction durable. Ces initiatives ouvrent la porte à l’innovation, éliminent les obstacles et favorisent la croissance mesurable de la part de marché.

CLT House | nArchitects |

Photo : Michael Moran

Alors que les États-Unis font face à une pénurie de 7,1 millions d’unités d’habitation abordables, la construction en bois ressort comme une solution efficace.

Dans le segment des maisons unifamiliales, les ressources de Think Wood jouent un rôle essentiel dans la protection et la croissance de la demande en bois d’œuvre résineux tout en étendant l’influence du bois dans des secteurs plus vastes.

Deux nouvelles études de cas de Think Wood démontrent que les systèmes de bois permettent de résoudre d’importants défis de conception et de développement tout en proposant des modèles reproductibles pour accélérer l’adoption dans les marchés.

face aux contraintes du monde réel

CLT House | nArchitects |

Photo : Michael Moran

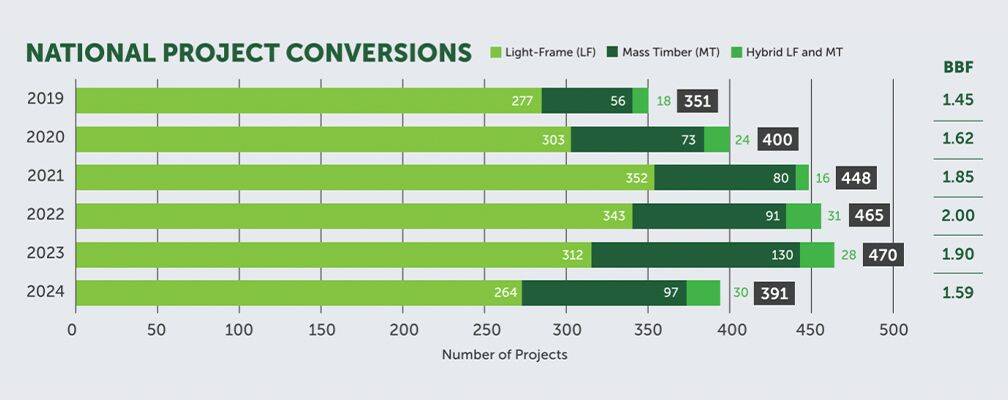

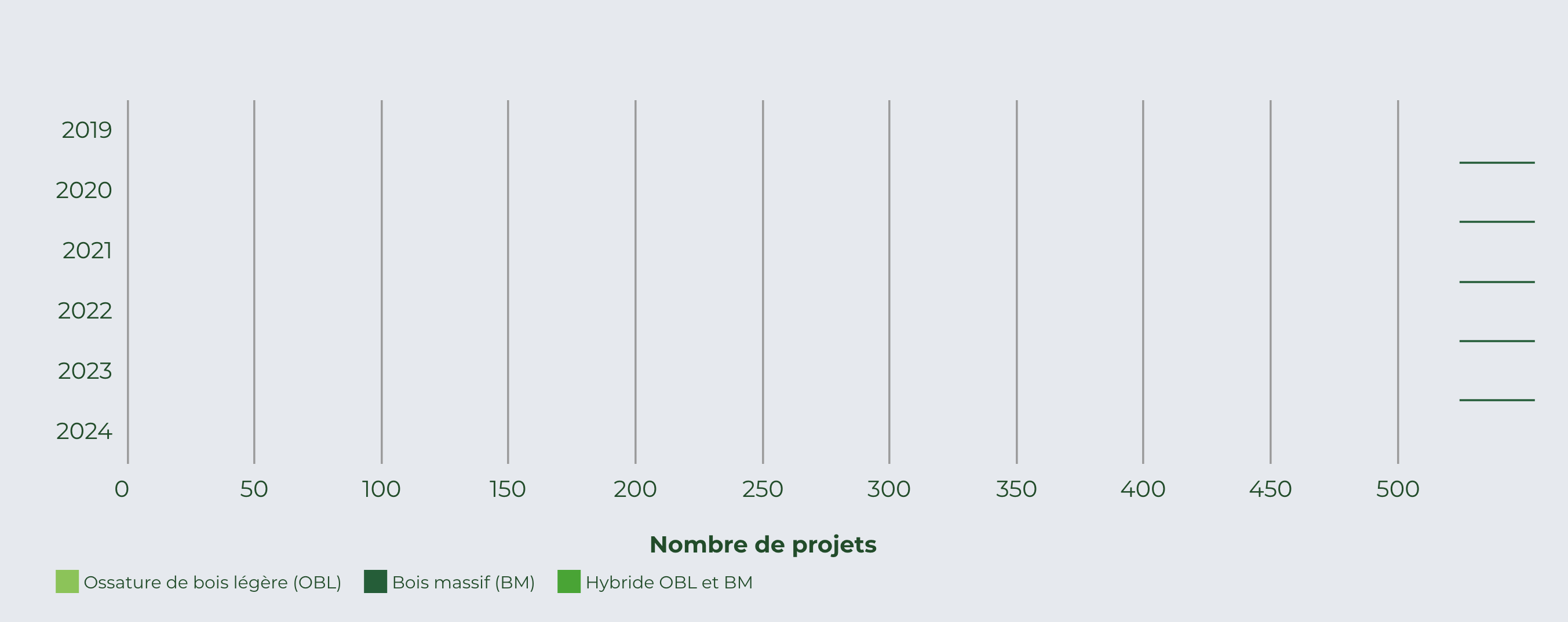

WoodWorks travaille directement avec les équipes de conception et de construction pour soutenir et influencer les projets, convertissant 2 525 projets au bois entre 2019 et 2024. En collaboration avec l’AWC, Think Wood et SLB Education, les programmes de SLB sont le moteur de la croissance de la demande pour l’industrie du bois.

391

30

97

264

470

28

130

312

465

31

91

343

448

16

80

352

400

24

73

303

351

18

56

277

1,59

1,90

2,00

1,85

1,62

1,45

Milliards

de pieds-

planche

Cette stratégie unifiée soutient l’objectif du SLB de générer 2,9 milliards de pieds-planche de demande supplémentaire annuelle d’ici 2035, en s’appuyant sur une solide feuille de route : 16,4 milliards de pieds-planche de demande supplémentaire et un rendement de 44 dollars pour chaque dollar investi. Ensemble, ces programmes assurent le leadership continu du bois d’œuvre en ce qui concerne la construction durable de haute performance, en plus de veiller à la croissance à long terme de l’industrie. En savoir plus.

Les programmes du SLB se concentrent exclusivement sur la croissance stratégique et résiliente de l’industrie du bois d’œuvre résineux, en s’adaptant et en changeant de cap au gré des conditions du marché. En tant que commanditaire majoritaire de l’AWC et de WoodWorks, ainsi que commanditaire principal de Think Wood et de la division de l’éducation, le SLB fournit la structure, la coordination et les investissements nécessaires pour poursuivre la progression du bois d’œuvre dans tous les secteurs de l’environnement bâti.

Ensemble, ces programmes forment un écosystème puissant : L’AWC protège et consolide la place du bois dans les codes et les normes du bâtiment, WoodWorks convertit des projets concrets et forme des constructeurs et des ingénieurs, Think Wood sensibilise les équipes de projet et oriente leurs préférences, alors que la division de l’éducation du SLB favorise l’adoption rapide du bois en intervenant auprès des étudiants et des professeurs.

Jackson Hole History Museum | HGA

Photo : Albert Vecerka

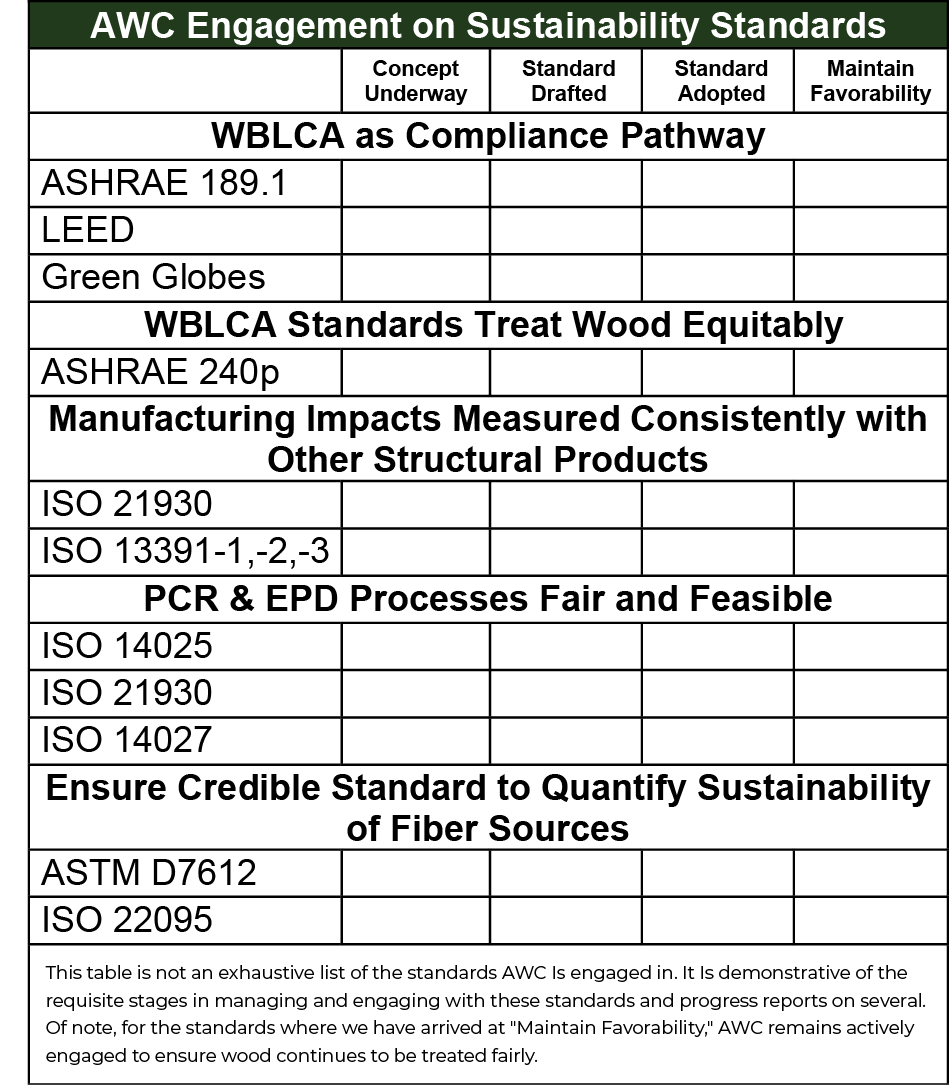

Alors que la transparence et les déclarations sur le carbone sont désormais un aspect essentiel du choix des matériaux pour la conception de bâtiments, l’AWC s’affaire à maintenir le caractère concurrentiel et la juste représentation du bois.

Lorsque la campagne « Build With Strength » a été créée il y a dix ans pour empêcher l’inclusion du bois massif dans les I-codes et récupérer la part de marché du béton en s’appuyant sur les incendies de chantier pour remettre en question la sécurité du bois, le SLB a réagi en finançant et en soutenant l’AWC dans l’instauration d’un programme d’engagement avec les services d’incendie.

Il est essentiel qu’une puissante voix de l’industrie s’investisse dans la création des codes et des normes pour maintenir le caractère concurrentiel du bois d’œuvre, mais aussi l’équité, la sécurité et l’accessibilité des codes du bâtiment à l’échelle des États-Unis.

Jackson Hole History Museum | HGA

Photo : Albert Vecerka

Si vous avez des questions sur les rapports SLB, veuillez envoyer un e-mail info@softwoodlumberboard.org.

l'incidence du SLB de 2024

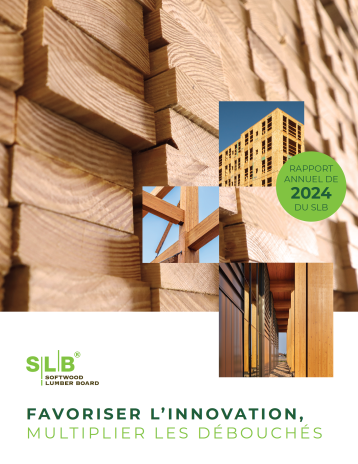

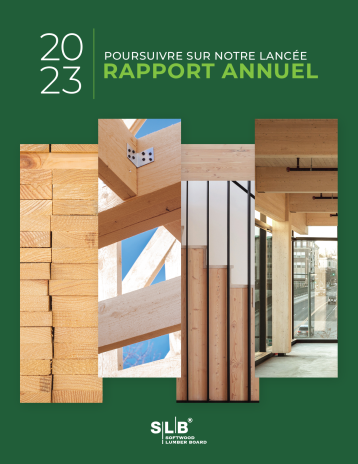

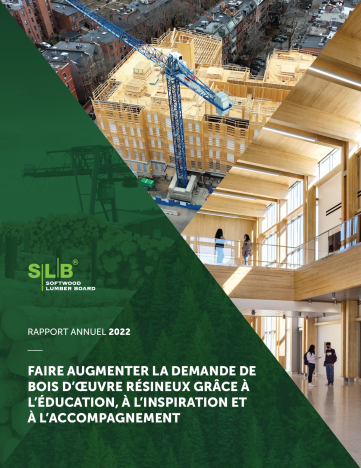

RAPPORTS PRÉCÉDENTS

Propriétaire |

Idaho Forest Group

Chef de la direction | Gorman Group

la vidéo correspondante.

Président et chefde la direction |

The Westervelt Company

ossature de bois légère

en bois massif

1 510 millions de pieds-planche en 2025.

la demande

de CO2 stockées

de CO2 évitées

Faits saillants du 3e trimestre

de pieds carrés

à ce jour

Ashlee Cribb

Vice-présidente de la division des produits de bois d’œuvre chez PotlatchDeltic Seconde vice-présidente, conseil d’administration du SLB

Coordination du programme du SLB

Vous aimeriez lire d’autres reportages du SLB?

Consultez ces articles.

Concours de bois massif K-12

Stratégie de croissance à cadre léger

Mercer Court | Ankrom Moisan Architects |

Photo : WG Clark Construction

Depuis 2015, les programmes financés par le SLB ont permis de convertir 2 300 projets d’habitation multifamiliale et 1 500 projets non résidentiels au bois d’œuvre. Chaque tranche de 100 $ investie par le SLB engendre un financement externe additionnel de 96 $ provenant de partenaires comme le USDA Forest Service, ce qui multiplie le rendement et prolonge l’effet sur le marché.

Un plan stratégique récemment approuvé profite de cet élan en recentrant l’attention sur les domaines qui génèrent des résultats : la conversion de projets (WoodWorks), l’intérêt pour la spécification (Think Wood), le soutien des codes du bâtiment (AWC) et les projets d’enseignement qui façonnent la nouvelle génération d’architectes, d’ingénieurs et d’entrepreneurs. Le programme d’accélérateurs urbains du SLB (qui va de Boston, de New York et de la Géorgie à Portland, en Oregon, et à Santa Monica, en Californie) a directement soutenu plus de 40 projets novateurs en bois, et d’autres villes devraient s’ajouter à cette liste en 2026.

En investissant dans le SLB, l’industrie renforce sa position actuelle sur le marché et garantit une demande supplémentaire pour l’avenir. En savior plus.

Alors que le segment des habitations unifamiliales est en baisse de 4,9 % à ce jour cette année, les producteurs de bois d’œuvre résineux subissent une pression renouvelée en raison de la volatilité des marchés et de la concurrence de l’acier, du béton et des composites. Le SLB demeure un joueur de premier plan dans la stabilisation de la demande et dans l’expansion de la portée de l’industrie dans les marchés multifamilial et non résidentiel.

« Notre industrie est confrontée à un problème de demande », admet Ashlee Cribb, vice-présidente de la division des produits de bois d’œuvre chez PotlatchDeltic et seconde vice-présidente du SLB. « Les sommes investies dans le SLB sont essentielles à l’expansion et à la croissance des marchés destinés à nos produits ».

dans un marché de la construction en transition

BuildFest 2025 | Peace Pavillion | Photo : Breyden Anderson

connaissances sur les solutions en bois et une préférence pour ce matériau aux professionnels établis et nouveaux ainsi qu’aux éducateurs.

Le nouveau plan stratégique du SLB vise à générer 2,9 milliards de pieds-planche de demande supplémentaire annuelle d’ici 2035, dont près de 1,4 milliard (environ 47 %) devrait provenir de la construction à ossature de bois légère, principalement dans le segment de l’habitation multifamiliale. Le chemin le plus rapide vers le volume est clair : se concentrer sur l’« entre-deux manquant » (les habitations qui font le pont entre les maisons unifamiliales et les édifices de grande hauteur), en plus des projets abordables où l’ossature de bois légère domine déjà sur le plan des coûts, de la rapidité et de la reproductibilité.

Cette stratégie s’appuie sur des gains confirmés et encourage les programmes financés par le SLB (l’AWC, Think Wood, WoodWorks et la division de l’éducation) à convertir d’autres projets d’habitation multifamiliale d’un à huit étages en faisant la promotion croisée des propositions de valeur bien établies de l’ossature de bois légère et des systèmes hybrides à ossature de bois légère et en bois massif. Parmi les mesures prioritaires figurent l’accélération de l’adoption des codes, le développement du soutien technique des projets et le renforcement de notre portée dans les régions qui présentent le plus de possibilités de croissance.

Du côté des promoteurs, l’analyse de rentabilité est éloquente : la diminution des délais de construction permet de réduire les coûts de financement, la rapidité accrue des locations permet d’accélérer le flux de trésorerie et les systèmes hybrides (comme les intérieurs en ossature de bois légère avec planchers ou noyaux en bois massif) offrent rendement et souplesse de conception sans gonfler les budgets. Ces avantages permettent d’augmenter le revenu net d’exploitation tout en réduisant le risque de livraison, ce qui joue un rôle primordial dans un marché du crédit

sous tension.

En concentrant les investissements dans les secteurs où les avantages de l’ossature de bois légère sont éprouvés et où l’adoption peut croître rapidement, le SLB dirige le bois d’œuvre vers une croissance annuelle soutenue et reproductible de 1,4 milliard de pieds-planche dans le seul secteur de la construction à ossature de bois légère. Découvrir la stratégie du SLB.

la demande d’ossature de bois légère de 1,4 milliard de pieds-planche par année

Williams College Davis Center | Leers Weinzapfel Associates |

Photo : Albert Vecerka Photographs

Ce projet de Portland, en Oregon, se compose de deux tours de quatre étages faites de planchers insonorisés en bois lamellé à goujons et de poutres et colonnes en bois lamellé-collé.

École secondaire de Cleveland

Le SLB et le USDA Forest Service ont annoncé les gagnants de la compétition sur le bois massif de 2025 : bâtir des écoles durables, qui attribue 1,8 million de dollars aux projets qui démontrent le pouvoir transformateur du bois massif sur la conception d’écoles de la maternelle à la douzième année. La compétition, qui en est à son troisième cycle, continue de faire croître la part de marché du bois d’œuvre dans le secteur à volume et à visibilité élevés de l’enseignement public.

Les écoles récipiendaires, de l’Oregon à Washington, D.C., démontrent la capacité du bois massif à produire des bienfaits mesurables : meilleure concentration des élèves, bien-être des occupants, réduction des délais de construction et réduction de l’empreinte carbone. Pour les investisseurs, le segment de la maternelle à la douzième année constitue l’une des possibilités de croissance les plus évolutives. Les projets retenus représentent des modèles conformes aux codes qui peuvent être reproduits partout aux États-Unis.

En intégrant la conception biophile et des matériaux durables, ces projets montrent que la construction en bois peut surpasser les systèmes classiques en matière de rentabilité, de durabilité et d’effet sur les collectivités. Chaque projet dévoilera ses données de performance et ses perspectives de conception afin d’accélérer l’adoption du bois dans les commissions scolaires. Par l’intermédiaire de la compétition sur le bois massif, non seulement le SLB finance l’innovation en conception, mais il permet aussi d’accroître la demande de bois d’œuvre résineux dans un segment de marché essentiel qui crée de la valeur pour les collectivités et, à long terme, pour l’industrie.

La compétition sur le bois massif est un autre exemple du partenariat entre le SLB et le USDA Forest Service pour débloquer l’innovation dans l’ensemble du secteur de la construction. Depuis l’officialisation de leur collaboration par l’intermédiaire d’un premier protocole d’entente en 2015, le SLB et le Forest Service ont conjointement investi près de 100 millions de dollars dans des programmes et des compétitions qui visent à élargir les marchés du bois d’œuvre résineux et à lui conférer le statut de solution de construction durable. Ces initiatives ouvrent la porte à l’innovation, éliminent les obstacles et favorisent la croissance mesurable de la part de marché.

profite de l’élan du bois d’œuvre dans les écoles de la maternelle à la douzième année

CLT House | nArchitects | Photo : Michael Moran

fait progresser l’utilisation du bois d’œuvre dans un segment en forte croissance

WoodWorks travaille directement avec les équipes de conception et de construction pour soutenir et influencer les projets, convertissant 2 525 projets au bois entre 2019 et 2024. En collaboration avec l’AWC, Think Wood et SLB Education, les programmes de SLB sont le moteur de la croissance de la demande pour l’industrie du bois.

Les programmes du SLB se concentrent exclusivement sur la croissance stratégique et résiliente de l’industrie du bois d’œuvre résineux, en s’adaptant et en changeant de cap au gré des conditions du marché. En tant que commanditaire majoritaire de l’AWC et de WoodWorks, ainsi que commanditaire principal de Think Wood et de la division de l’éducation, le SLB fournit la structure, la coordination et les investissements nécessaires pour poursuivre la progression du bois d’œuvre dans tous les secteurs de l’environnement bâti.

Ensemble, ces programmes forment un écosystème puissant : L’AWC protège et consolide la place du bois dans les codes et les normes du bâtiment, WoodWorks convertit des projets concrets et forme des constructeurs et des ingénieurs, Think Wood sensibilise les équipes de projet et oriente leurs préférences, alors que la division de l’éducation du SLB favorise l’adoption rapide du bois en intervenant auprès des étudiants et des professeurs.

Cette stratégie unifiée soutient l’objectif du SLB de générer 2,9 milliards de pieds-planche de demande supplémentaire annuelle d’ici 2035, en s’appuyant sur une solide feuille de route : 16,4 milliards de pieds-planche de demande supplémentaire et un rendement de 44 dollars pour chaque dollar investi. Ensemble, ces programmes assurent le leadership continu du bois d’œuvre en ce qui concerne la construction durable de haute performance, en plus de veiller à la croissance à long terme de l’industrie. En savoir plus.

continue de l’industrie du bois d’œuvre

Jackson Hole History Museum | HGA | Photo : Albert Vecerka

l'incidence du SLB de 2024

Si vous avez des questions sur les rapports SLB, veuillez envoyer un e-mail info@softwoodlumberboard.org.

RAPPORTS PRÉCÉDENTS